Quality has an alternative: QUALITY

Manufacture on the Steyr Site

The strategic set-up of the manufacturing facilities in Steyr, Austria is based around flexibility and speed. State-of-the-art technologies enable the highest operating efficiency and precision.

Manufacture of components

Our flexible mechanical manufacturing units of the latest generation enable machining processes such as grinding and honing (superfinishing) of bearing inner and outer rings.

Our machine park is configured for all bearing types, such as cylindrical roller bearings, deep groove ball bearings, tapered roller bearings and spherical roller bearings.

Assembly lines

The assembly of components are carried out on four interlinked production lines. Currently, the assembly in Steyr is focussed on bearings of medium to larger diameters. This assembly range comprises more than 5,000 bearing types and is continuously expanding.

Quality Process for Quality Bearings

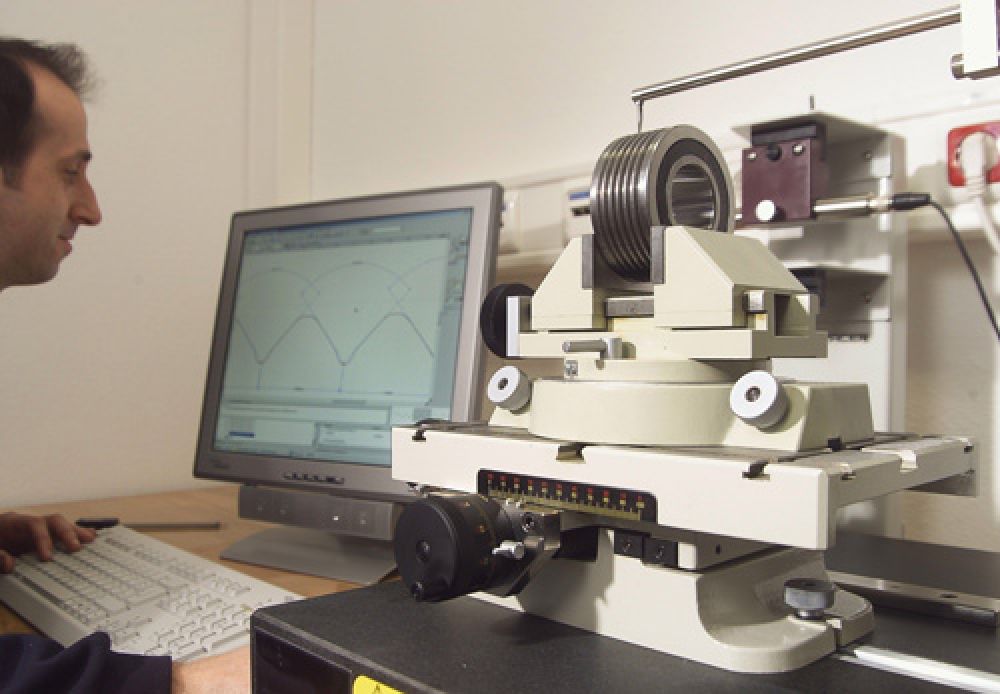

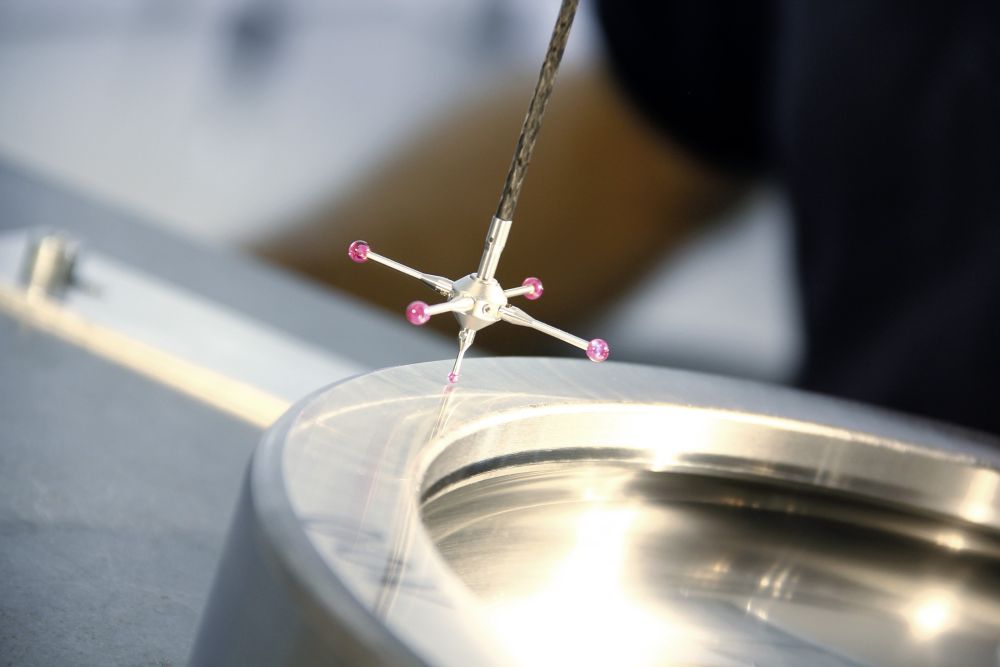

All NKE bearings undergo stringent, documented quality inspections at our headquarters in Steyr. By using advanced test and measuring equipment as well as a rigorous quality policy, we can guarantee that every single batch of bearings delivered to you is of the highest quality standard.

NKE’s Steyr site is certified to ISO9001 in the design, development, manufacturing and distribution of bearings. Here are a few examples of our test and measurement equipment:

- Material: Spectrometer (chemical analysis), hardness testing

- Dimension: Linear height measurement, shape and roughness measurement, CNC coordinate measuring system, roundness measurement, measuring station for large size bearings

- Function: Noise/vibrations testing modules (GP1 and GP2)

Besides our in-house facilities, we also commission external independent laboratories for regular or special inspections to ensure the highest quality of NKE bearings.

Quality has an alternative: QUALITY

The uncompromising pursuit of quality is our highest priority and a cornerstone of our success. This quality process starts with engineering and commercial service, where customers’ requirements are analysed and implemented. Through out the complete supply chain - from the first customer contact till after sales service - we aim at "zero defect".

Through proactive quality management we implement measures and regular checks across all processes to prevent defects.

All NKE bearings undergo stringent and documented quality inspections at our headquarters in Steyr. By using advanced test and measuring equipment as well as a rigorous quality policy, we can guarantee that every single batch of bearings delivered to you is of the highest quality standards.

rolling!

Austria Quality Seal

Austria Quality Seal

The Austria Quality Seal is an official guarantee for Austrian quality products. The quality seal is awarded by the Austrian Association for the Promotion of Quality (ÖQA) after stringent quality inspections by an authorised certification body.

Supply chain

Like other leading bearing manufacturers, NKE AUSTRIA does not produce all components in-house. All NKE standard and special bearings are designed and optimised by NKE engineers in Steyr, Austria. Components and assemblies are manufactured as precision products strictly according to NKE specifications by our audited and qualified production sites in Europe and Asia. Further processing, critical processes and quality assurance, however, are undertaken only at NKE’s headquarters in Steyr, Austria.

Declaration of product supply

A prerequisite for the Austria Quality Seal is that at least 50 percent of the value creation of all NKE bearings is generated in Austria. Due to various levels of production processing performed in Austria, products may carry one of the following declarations of product supply

"Made in Austria"

In addition, further substantial production processing is undertaken in the Steyr manufacturing plant. These products fulfill the requirements for the “Made in Austria” status. As of the end of 2006, more than 4,000 items in the NKE product range are made in Austria.

Chinese

Chinese