Conveyor Belts

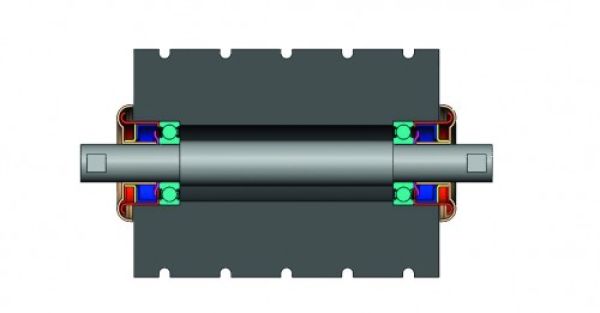

One of the most vital parts of the rollers/idlers in the conveyor belts are the bearings.

The main objective of the rollers and stations on a conveyor belt is to shape the belt, provide support for the minerals transported and reduce resistance to movement, so that the material is transported at the lowest cost.

In the opencast mining industry, the conveyor belt roller systems are subject to the following operational factors, among others:

- Working conditions: High loads and possible impact loads.

- Additional loads due to shaft deflection and vibrations.

- High turning speeds.

- Unfavorable weather conditions, extreme temperature variations, humidity, rain and snow.

- High level of external contamination.

Although the ball bearings used in the rollers have been correctly selected, are sealed and lubricated, this does not mean that the aforementioned working conditions do not affect them.

Especially the tremendous pollution in the mining environment, can infiltrate impurities that will cause unwanted effects. These will not only reduce the bearing-life, but will also have consequences on the performance and reliability of the rest of the components of the conveyor-system.

The single row ball bearings designed by NKE, especially for conveyor belt rollers, are engineered to operate under the most adverse conditions.

NKE's new and special bearing design for conveyor belt rollers, will help substantially to reduce the incidence of the following issues with positive results:

- Reduction of fire risks.

- Extend the duration of the belt.

- Contribute to the reduction of energy consumption.

- Improve the conveyor-system reliability.

- Contribute significantly to the reduction of operationing costs.

The most common bearing sizes for this application rangefrom 30mm to 50mm inner diameter.

Designed by NKE to operate in the most adverse conditions, the deep groove ball bearings, especially for the usage on conveyor belt rollers, are the result of extensive analyses that have allowed the introduction of the following improvements that will guarantee a better performance compared to the standard bearings:

- Special cage design with low friction synthetic material.

- Improved raceway geometry.

- Special radial internal clearance.

- NKE special design shields, contacting and low-frictionNKE special design shields, contacting and low-friction seals.

- Carefully specially selected grease with a broadoperating temperature range to resist thermal variations.

Chinese

Chinese